ESG Topics A-Z

Waste

To PepsiCo:

Managing our operational waste represents an important opportunity to keep material out of landfills. Reducing waste also helps PepsiCo in its efforts to mitigate reputational risk and minimize costs, including fees to facilities that accept waste.

To the World:

Put simply, waste is symptomatic of an inefficient use of resources. The World Bank estimates global waste will increase by 70% by 2050 without action.1

Approach

Waste reduction is a strategic imperative for PepsiCo and contributes to our pep+ (PepsiCo Positive) ambitions. It not only provides benefits to our business in the form of cost savings and efficiencies gained, but is also inherent to being a good citizen of the communities where we operate.

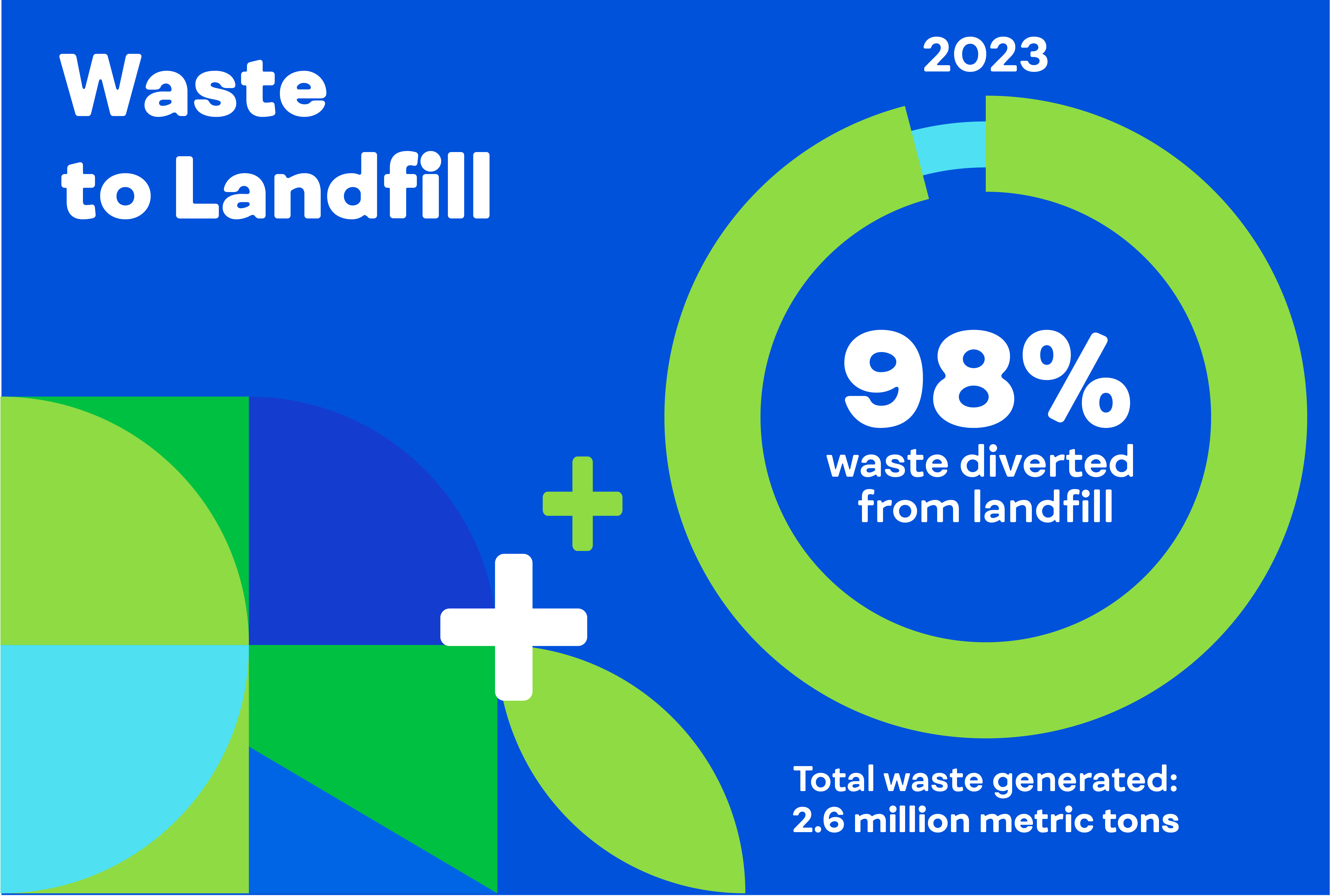

PepsiCo is working toward achieving a 99% diversion rate by 2025 in its direct manufacturing and warehouse operations. While we work towards this objective, we strive to achieve virtually zero waste to landfill, which we define as 98% landfill diversion rate or greater, in our direct operations, including offices and other non-manufacturing facilities. Though managed at the site level, progress is aggregated globally by PepsiCo’s Sustainability Office, and the total volume of waste generated from our company-owned manufacturing and warehouse operations is independently assured on an annual basis.

We manage our supply chain and marketplace waste and associated costs through our End-to-End (E2E) Materials Waste Program. The program, led by Strategy & Transformation, manages waste across much of the value chain, from raw materials and manufacturing to warehouses and sales operations. The program is now present in most PepsiCo-operated facilities, and we are working to improve E2E capabilities in all markets.

Our E2E waste program covers waste across four key areas of waste development within our operations:

Raw material waste

We generate raw material waste when packaging and/or ingredients become obsolete or when raw ingredients reach their expiration date and are no longer usable in production, as indicated by food safety standards.

As a global convenient foods and drinks company, we have an interest in addressing the issue of food waste. Globally, approximately one-third of the food produced for human consumption is wasted each year,2 and that waste is a significant contributor to greenhouse gas (GHG) emissions.

Our efforts to reduce food waste focus on using agricultural inputs as efficiently as possible in our manufacturing processes and finding innovative solutions for using the organic material that remains, including fertilizer production and biogas feedstock. We are continuously improving our equipment and manufacturing processes as well as planning methods to ensure an optimal use of raw materials.

Manufacturing waste

We pride ourselves on manufacturing efficiency, but we nevertheless work towards continually reducing waste in the process. Manufacturing waste is driven primarily by process disruptions such as start-ups, line changes and shut-downs; quality issues; breakage and repacking. Plant teams strive to reduce it by efficiently sequencing production lines, reducing changeover waste and improving packaging quality, to reduce breakage and damage.

Warehouse waste

As our products move from manufacturing to distribution and ultimately to our customers, we may generate waste at several points along the chain such as when products are damaged or expire.

Strategies to reduce warehouse waste include the addition of analytical tools that monitor and detect deviations from the ideal process path (e.g., product on hold or blocked longer than expected), and flag when products are nearing their expiration date and have not been shipped. The warehouse team can then ensure the product at risk is shipped fast and can also work with sales teams to use promotion strategies that move the product faster.

When finished goods are not salable, but still safe to consume (i.e., aesthetically damaged or with too short of a shelf life for store turnover rates), they are often donated to local communities or used as samples.

Sales waste

During the course of getting our products to store shelves, waste is generated through breakage, product expiration and changes in product (labeling, flavors) that make the product no longer eligible for sale. To reduce sales waste, our E2E Waste Team works closely with sales to understand demand planning and reduce the risk of over-stocking as well as with route sales representatives to develop solutions to avoid product breakage.

Hazardous waste

Beyond our E2E waste program, PepsiCo tracks and manages hazardous waste created in our company-owned operations. The precise definition of hazardous waste differs regionally but can include lab materials and maintenance residue such as gearbox oil, lights and batteries. In total, hazardous waste comprises less than 1% of our total waste stream. Our global and regional Environmental, Health and Safety teams oversee this waste to help ensure we are fully compliant with local governmental requirements.

Progress

Waste to landfill

In every community where we operate, we are working to minimize the amount of waste that we send to landfill through our direct operations, covering raw materials, manufacturing and warehousing. In 2023, we generated 2.6 million metric tons of waste in our manufacturing and warehouse operations, of which we diverted from landfill over 2.5 million metric tons, or 98% of total waste.

End-to-end waste

To help meet our E2E waste objectives, we’ve developed a series of tools and platforms to help us better analyze, track and manage our waste. The program is now present in a great majority of PepsiCo markets across all sectors and includes tools such as:

- Automated Waste Diagnostics: A series of dashboards to provide visibility to waste spend, visualize waste trends and benchmark against successful facilities. In 2023, we expanded automation to the remaining LATAM markets beyond Mexico and Brazil.

- E2E Waste Playbooks: Documents that provide a step-by-step framework to assess waste performance and unlock savings opportunities within the value chain. The playbooks provide tools to review best-in-class practices, share market-tailored solutions and gain insight into waste innovation.

- PepsiCo Champions League: A competitive program allowing different facilities to compete against and learn from each other about waste reduction best practices.

The central E2E Materials Waste team works closely with our waste leads network in our business units to develop standardized processes and tools to mitigate the major and most common waste factors across our operations.

Reduce food waste

We strive to reuse materials in productive ways. PepsiCo collaborates with its partners to identify beneficial uses for the processing residue that remains from manufacturing. For example, a new biogas program at our Carregado, Portugal factory will use a biodigestor to convert potato peels, food waste unfit for consumption and sludge produced at our on-site wastewater treatment plant to biogas, which we can then use as a replacement for natural gas. The Carregado project is expected to recover over 20,000 tons of organic waste into fuel, helping to reduce the GHG impact of our production processes by 30%. For more on our progress with renewable fuels, see Renewable energy.

Progress

In 2023, we diverted 98% of our operational waste from landfill.

Challenges

Recycling infrastructure is not always in place in areas where PepsiCo manufactures its products. Where this is the case, we are working with local partners in an effort to support the development of the necessary infrastructure.

Strategic partnerships

PepsiCo maintains partnerships with organizations that help us to reduce the waste we send to landfill. These include recycling, composting and waste-to-energy businesses. Building a strong local infrastructure for these activities helps us to meet our ambitions while also strengthening local economies and reducing waste beyond our own operations.

What's next?

We plan to remain focused in the coming years on achieving 99% waste diversion in direct manufacturing and warehouse operations, particularly in the developing markets, where we are building recycling infrastructure in our operations and embedding a culture of recycling.

Through our E2E waste program, we plan to work towards:

- Promoting a culture of zero-waste;

- Enhancing waste reporting tools; and

- Innovating to reduce with predictive analytics.

1Kaza, Silpa; Yao, Lisa C.; Bhada-Tata, Perinaz; Van Woerden, Frank. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050. World Bank, 2018

2UNEP Food Waste Index Report, 2021

Related topics

Disclosures

Last updated

June 19, 2024